Ginger Powder Processing Line

| Machine Name | Power |

| Ginger Washing Peeling Machine | 1.5kw |

| Ginger Slicing Machine | 1.1kw |

| Ginger Drying Machine | 12.45kw |

| Ginger Powder Grinding Machine | 7.5kw |

| Ginger Power Packing Machine | 1kw |

You can now ask our project managers for technical details

The ginger powder processing line combines various ginger machines that process original ginger into excellent ginger powder. It contains a ginger washing machine, ginger peeling machine, ginger slicer, ginger drying machine, ginger grinder, and ginger powder packaging machine. Ginger powder is popular in many areas, and it has huge health benefits for humans. Therefore, the ginger business is a good choice with a small investment and a great return.

TAIZY ginger machines enjoy a simple structure, stainless steel body frame, and quality parts. Besides, we offer powerful custom services to meet the requirements of different food processing plants, restaurants, hotels, etc. If you want to start your ginger business, contact us for more useful information to benefit your project.

Benefits of ginger powder production line

- Ginger powder processing line one-time ginger slice dosage, less capital, the equipment itself has good insulation performance and low energy consumption.

- Compact structure, easy to operate, reliable in use, easy to disassemble and install. Simple installation, as long as there is shelter from the wind and rain can be installed and used.

- Clean, powerful, large air volume, hot air, fast drying, simulating the principle of natural air drying, ginger slices/ginger powder natural color, natural flavor to maintain good.

- All ginger powder processing machines are made of food-grade materials with stable structures.

- High efficiency. The drying efficiency of ginger slices is several times higher than that of various heat source air energy heat pump ovens and baking ovens. It greatly shortens the drying time of ginger slices and reduces the equipment capital and labor costs.

- The ginger powder processing machine has a variety of outputs to choose from, with semi-automatic and fully automatic machines. The basic output of this ginger powder production line is 500kg/h-1t/h. Of course, we can customize the output of this processing line according to the production requirements of our customers.

Technical data of TAIZY ginger powder processing line

| Machine Name | Power | Voltage | Dimension |

| Ginger Washing Peeling Machine | 1.5kw | 380V50Hz | 1580*850*800mm |

| Ginger Slicing Machine | 1.1kw | 380V50Hz | 690*560*880mm |

| Ginger Drying Machine | 12.45kw | 380V50Hz | 1500*1200*2200mm |

| Ginger Powder Grinding Machine | 7.5kw | 380V50Hz | 700*600*1450mm |

| Ginger Power Packing Machine | 1kw | 380V50Hz | 1000*900*1850mm |

These are the parameters of the individual machines included in the ginger powder making equipment. You can get a clear idea about the dimensions of each machine. This can be easy for you to determine the size of s ginger processing plant.

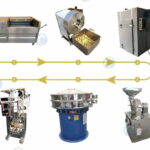

Flow chart of ginger powder manufacturing line

The ginger powder processing line contains various ginger machines, which can turn original ginger into excellent ginger powder. Taizy ginger powder production process includes:

Ginger cleaning washing → ginger peeling → ginger cutting slicing → ginger slices drying → dried ginger slices grinding → ginger powder packaging.

Machine details of the ginger powder production line

The ginger powder production line is an integrated plant of several machines. So what machines are used in the ginger powder production line? There are details are as follows:

Ginger washing and peeling machine: Commercial ginger cleaning and peeling machine is a kind of brush type washing machine. The machine mainly realizes the washing and peeling function through the friction between the brush and the ginger. When peeling, the machine is also connected to a water pipe to spray water. Therefore, after peeling, the ginger skin can be cleaned with high pressure water spray.

Ginger slicing machine: The washed and peeled ginger is quickly sliced with a professional ginger slicer. The thickness of the slices is about 3mm to achieve the ideal drying effect. Air-drying is required after slicing to quickly remove excess water from the surface of the ginger slices.

Ginger drying machine: The dryer is mainly applicable to the dehydration of ginger slices. The ginger slices dryer is not only suitable for ginger powder production line, but also widely used for drying fruits, vegetables, medicinal herbs, and other products. And the machine is very intelligent, it uses an intelligent control panel to control the whole drying process. The ginger slices dryer can adopt various heating methods such as electricity and steam. And there are many models, which can meet the needs of customers with different specifications.

Ginger grinding machine: Dried ginger slices enter the crushing chamber through the conveying device for crushing and pulverizing. Different mesh screens can be configured according to the customer’s requirements for the fineness of the ginger powder.

Ginger powder packaging machine: After the ginger powder is ground into powder, different ginger powder packing machines are configured by customers according to the packaging form of ginger powder to meet various needs of customers.

Contact us

As a professional ginger powder production line manufacturer, we can customize the machine to meet your needs. Whether it is a semi-automatic production line or a full-automatic production line, we can provide them all. What are you waiting for, hurry up and contact us.