¿Cómo ayudó nuestra máquina peladora de piel de cebolla a nuestros clientes israelíes?

En el proceso de procesamiento de cebolla, pelar suele ser el paso que más tiempo consume y requiere más mano de obra, además de ser el que más probabilidades tiene de causar desperdicio de materia prima. Este artículo explicará cómo nuestra máquina peladora de cáscaras de cebolla ayuda a nuestro cliente israelí a resolver los problemas de producción.

Antecedentes y necesidades del cliente

Nuestro cliente israelí se dedica al procesamiento primario de verduras y necesita manejar una gran cantidad de cebollas frescas diariamente. Su máquina peladora de cebolla actual tiene las siguientes desventajas:

- Baja eficiencia

- Altos costos de mantenimiento

- Alta tasa de deterioro de cebollas

Por lo tanto, el cliente desea introducir una máquina peladora de cebolla con estructura estable, capacidades de pelado limpio y apta para operación continua, para mejorar la eficiencia general del procesamiento y reducir los costos laborales.

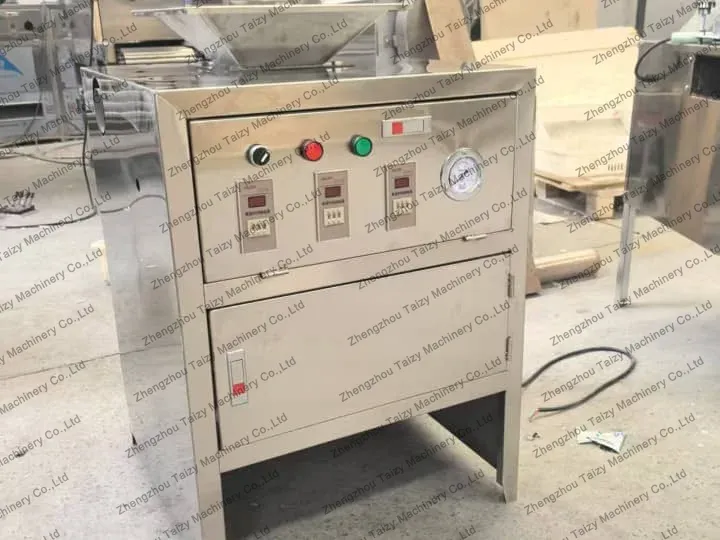

Soluciones: TZ-150 Máquina peladora de cáscaras de cebolla

Basándonos en las características de la materia prima del cliente y los requisitos de capacidad de producción, Taizy recomendó la máquina peladora de cebolla TZ-150. Esta eliminadora de cáscaras de cebolla tiene las siguientes características:

- Alta eficiencia de procesamiento, con una velocidad de 100-150 kg/h.

- Minimiza el daño a las cebollas, asegurando su integridad.

- El equipo es fácil de operar y puede ser manejado por una sola persona.

- Fácil de mantener y adecuado para operación continua a largo plazo.

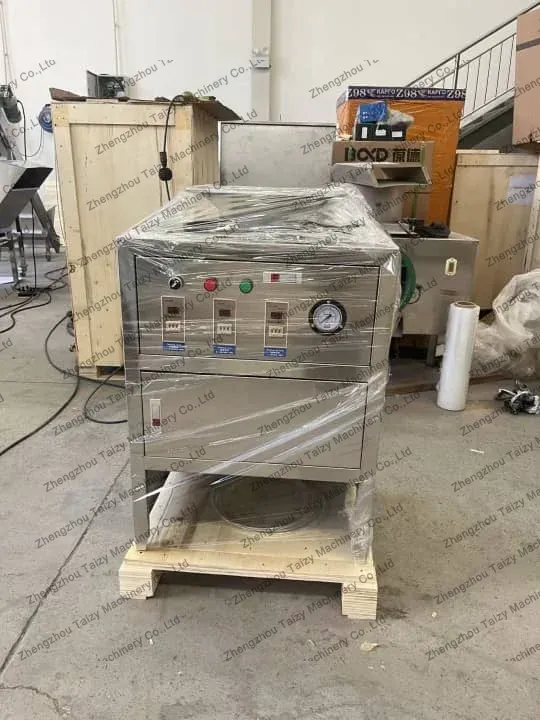

Transacción y envío exitosos

Después de confirmar la configuración del equipo de pelado de cebolla y los requisitos técnicos, firmamos con éxito el pedido con el cliente. Rápidamente organizamos la producción y las pruebas, y la máquina peladora de cáscaras de cebolla fue empacada de forma segura en cajas de madera resistentes. Luego fue enviada a Israel por vía marítima.

Resultados de la cooperación

Después de que se puso en uso el pelador de cáscaras de cebolla, la eficiencia de procesamiento del cliente mejoró significativamente y se redujeron los costos laborales. Además, el efecto de pelado fue limpio y la tasa de deterioro de la cebolla disminuyó. ¡El cliente elogió mucho la estabilidad de la máquina peladora de cebolla Taizy!